shapewave

Manufacture structural inflatables with unparalleled freedom in shape and material options.

UNLEASHYOURSHAPE THE INFLATABLES OF YOUR DREAMS ARE HERE TECHNOLOGY

Our proprietary shapewave® robot welding technology enables us to manufacture structural inflatables with unparalleled freedom in shape and material options.

Thanks to our patented CAD-to-weld tool chain, we are able to weld thousands of tapes in just hours, with high accuracy and great bond strength.

The weld head is designed to build each individual tape connection with a unique length as well as a an angled weld line, allowing complex inner structures to perfectly match the intended inflated shape.

With a pressure range of up to well over 1 bar (14 psi) yet maintaining a safety factor of over 5, the stiffness and smoothness you may know from inflatable SUPs are within reach.

SHAPEWAVE® WAVEMAKER01

The wavemaker01 is a fully automated welding robot which boasts the ability to perform welding at a stunning rate of one weld per second, offering unparalleled precision and remarkable flexibility in various aspects, including bi-axial weld angles, tape length, width, and more.

With the wavemaker01, we enable you to effortlessly “3D print” inflatable structures, giving you unprecedented creative freedom directly from your CAD model.

Our shapewave® farms will be operating numerous wavemakers to meet demand. Smaller and larger, as well as high-efficiency multi-head shapewave® wavemakers are currently being developed to meet market needs.

FAQs

SHAPEWAVE® WAM (WEBBING ALLOCATION MODULE) SOFTWARE

When we embarked on the journey to engineer our wavemaker01 we immediately realized the project depends on good design software to automate the placement of the tape. A good robot can't navigate without a good map! So we created WAM, our proprietary Webbing Allocation Module.

With WAM , you can effortlessly import any 3D design file and witness real-time magic unfold. WAM automatically calculates crucial parameters such as tape positions, tape lengths, tape angles, final built weight and material requirements, simplifying cost calculations. It allows designers to customize the design and adjust parameters to preview the inflated part almost in real time before the materials are loaded on the wavemaker01 for some WAM-CAM!

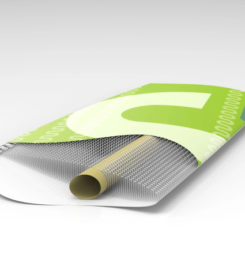

BRING COLOR TO YOUR DREAMS

The shapewave® membranes can be digitally printed with intricate, full-colour designs to make your designs pop! Pre-printed material will be fed via rollers into the Wavemaker01 while the WAM software takes your CAD drawing, welds the internals and creates the shape of your final design.

As an added benefit we only need to keep white material in stock, which also makes it easier to recycle cutting waste. Other types of material can be used depending on the final product application.

USE CASES

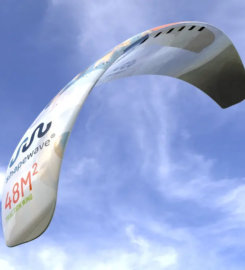

>> HAND HELD WINGS <<

Built with shapewave®, hand held wings can finally have an optimized aerodynamic profile and enhanced

stiffness at the same construction weight as current LEI constructions.

Due to the even load spreading, canopy materials suffer less stress and are therefore expected to last for many seasons.

pressure class 0.20 - 0.35 bar

>> WINGSAILS <<

shapewave® wingsails provide an economical, safe and rollable alternative to cumbersome and unsafe constructions used in modern sail racing.

Our WAM software is trained to wrap tapes around internal objects such as inflatable structural beams, to keep the membranes from bulging in otherwise unsupported areas.

pressure classes:

0.15 - 0.25 bar for shapewave® fairings

0.5 - 1.0 bar for beam